Automotive Electrification Project

MG ZS 4WD PHEV was a prototype hybrid vehicle designed and built from a conventional SUV. The final product, fully designed, tested and built by interns, improved the original vehicle’s efficiency by adding a 15-mile range with zero emissions, as well as four-wheel drive (4WD) capability to improve performance in adverse weather conditions. The vehicle was able to regenerate electricity during braking and was charged through a domestic socket.

Info

2017 - 2018, 10 months, Team of 10

Role

Project Manager

Context

Industry Project @ SAIC Motor Technical Centre UK

Skills

Project Management, Leadership, Communication, Team Work, Procurement, Testing, Workshop Work

Tools

Microsoft Projects, PowerPoint, CATIA V5, MATLAB, Simulink

The Challenge

Car manufacturers are more than ever looking into alternative and greener solutions to reduce vehicle emissions to meet the targets imposed by the new WLTP cycle. Executive Committee members of SAIC Motor challenged a group of 10 interns to convert a conventional MG SUV into a 4WD Hybrid Vehicle. As Project Manager, I was accountable for the final product. Due to the project scope being purposely vague, we were responsible for developing our own specification, which required in-depth research and benchmarking during the initial phase.

The Process

The various challenges included modifying the rear suspension of the vehicle to allow for a driven axle, design, purchase and packaging of the electric powertrain and the control system. My role as Project Manager consisted in overviewing the design process, ensuring that all parts were designed, built and tested to match the quality expected by the Executive Committee. Leading our team meetings, dealing with suppliers and reporting on a regular basis to our stakeholders were also my responsibilities.

The entire rear end of the SUV was removed

The suspension was modified to make space for the drivetrain

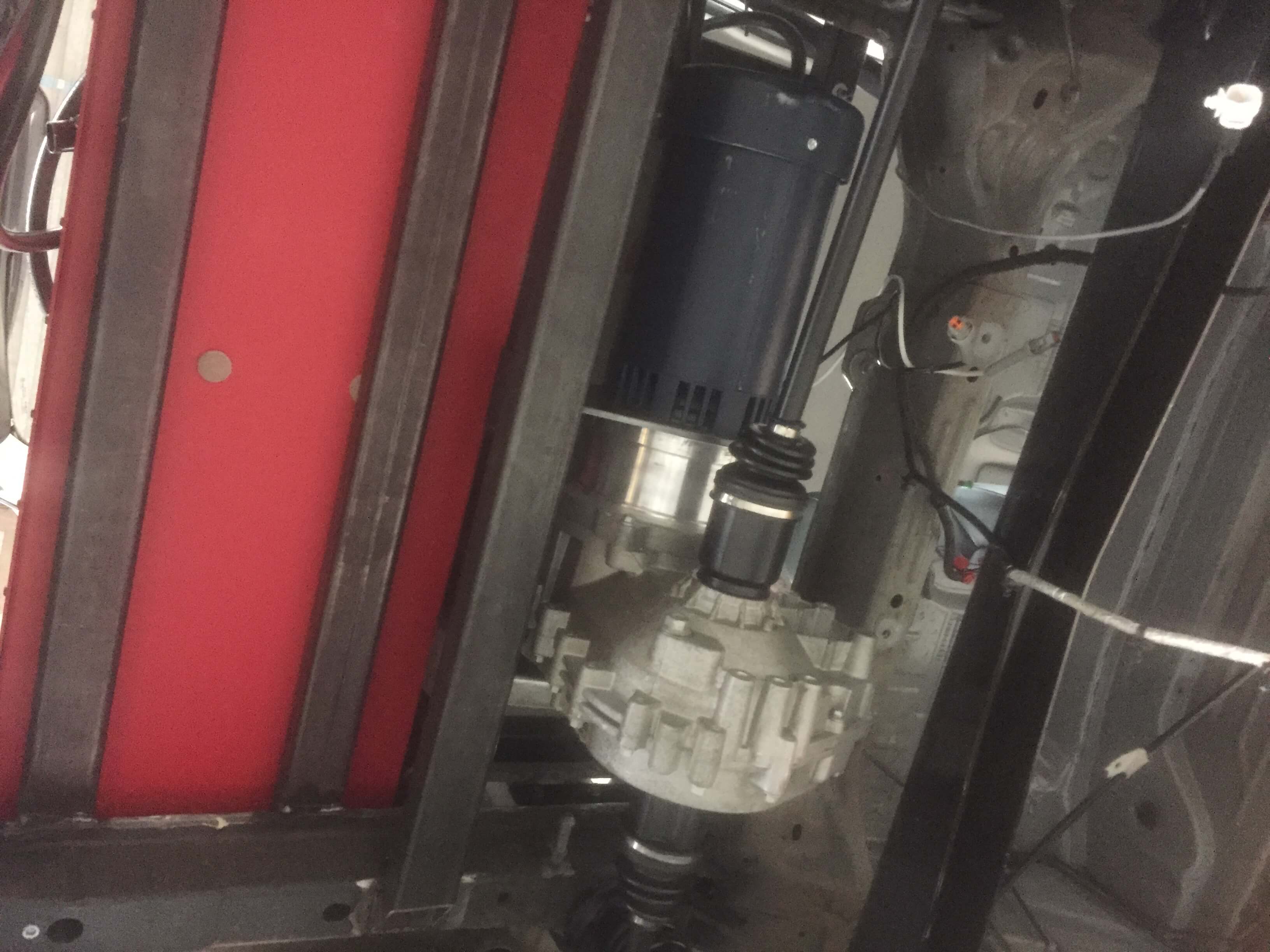

Bottom view of the motor, gearbox and battery

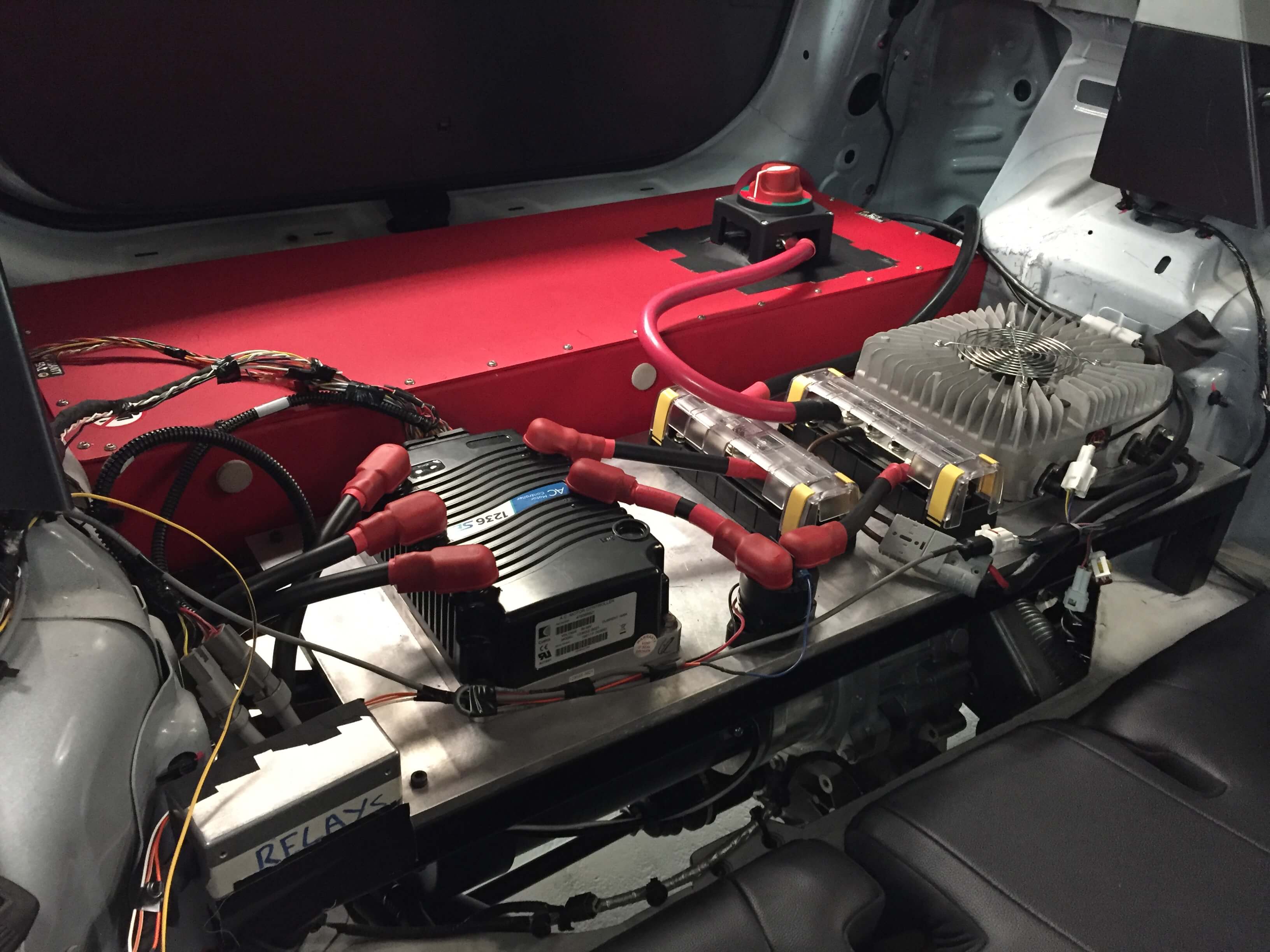

Top view of the electrical system including the charger, battery and motor controller

The Result

The final product improved the original vehicle’s efficiency by adding a 15-mile range with zero emissions, as well as 4WD capability to improve performance in adverse weather conditions. The vehicle was able to regenerate electricity during braking and could be charged by plugging it to a domestic socket. The project was completed in time, under the budget limit and created a great impression amongst the Executive Committee members.

Video from the outside of the car being driven in electric mode

Video from the inside of the car being driven in electric mode